PE high-pressure bags, fully named polyethylene high-pressure bags, are a kind of plastic packaging bags made from low-density polyethylene (LDPE) as the main raw material through processing techniques such as blow molding.

Low-density polyethylene is usually the product obtained by the polymerization reaction of ethylene monomers under specific conditions of high temperature (160 - 300 °C) and high pressure (100 - 300 MPa). PE high-pressure bags made from it inherit many characteristics of low-density polyethylene.

PE high-pressure bags are soft and elastic in texture, comfortable to the touch, and have excellent flexibility. They can be easily bent and twisted without being easily damaged, which enables them to conform well to the shape of the packaged items. Whether the items are of regular or irregular shapes, they can all be tightly wrapped by these bags.

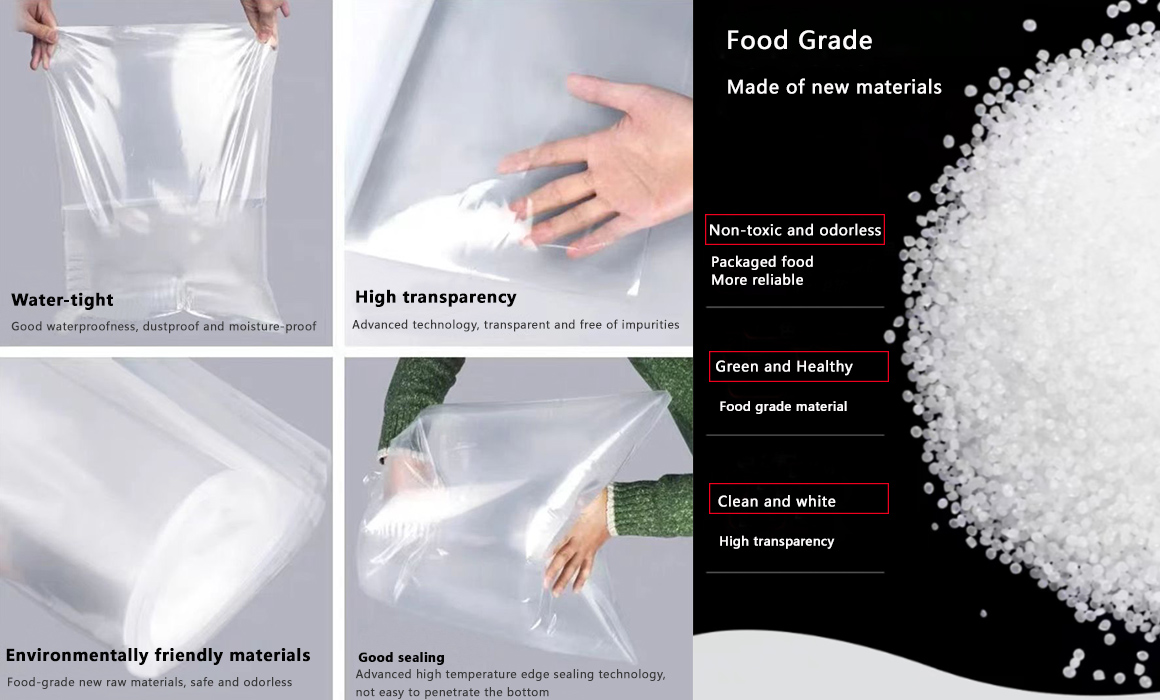

They have relatively high transparency, which facilitates clearly presenting the appearance of the items contained in the bags and gives them certain advantages in product packaging and display. Meanwhile, PE high-pressure bags also have good moisture resistance, a certain degree of water resistance and good chemical stability. When in contact with common chemical substances, they generally do not easily undergo chemical reactions, so they can play an effective protective role for products in various environments.

In addition, PE high-pressure bags also have good tensile properties and elongation rates. They are not prone to rupture when subjected to a certain external force. However, their tensile strength is slightly lower compared with that of some other types of polyethylene bags (such as high-density polyethylene bags).

In practical applications, PE high-pressure bags are widely used in the packaging fields of numerous products such as food, daily necessities, textiles, and electronic products, meeting the various requirements of different products for packaging bags in the links of packaging, transportation, storage and sales.